COREtec Originals VV023 Dodwell Oak 5"

The floor that started it all with our patented and revolutionary waterproof, rigid WPC core. Available in hundreds of styles and colors that provide comfort for life.

-

Realistic wood looks and textures in various sizes

-

Cork backing makes them quieter and warmer underfoot

-

Backed by a limited lifetime residential warranty

Layers

-

UV Acrylic Finish

Durable: Provides superior stain resistance and cleanability.

-

Wear Layer

Maintenance Free: Protects against excessive wear and stains. Never needs sanding, sealing or refinishing.

-

Luxury Vinyl Design Layer

Looks: COREtec offers the widest selection of designs.

Textures: Detailed embossing and beveling.

-

COREtec Core Structure

100% Waterproof: Won’t warp or buckle.

Easy To Install: Angle tap system can be installed easily over existing floors.

Comfortable: Thicker WPC core is softer underfoot.

-

Attached Cork Underlayment

Quiet & Warm: Natural cork underlayment blocks out chills and noise.

RESILIENT Installation Guidelines for WPC Products

I. GENERAL INFORMATION

These installation guidelines apply to the WPC products only. All instructions and recommendations should be followed for a satisfactory installation.

-

Acclimation of material prior to installation is not required; however, the floor covering should be installed in a climate controlled environment with an ambient temperature range between 55°F - 85°F (13°C-29°C) or average temperature of 70°F (21.1°C).

-

For installations involving 3 season scenarios, meaning, the dwelling or installed space is without climate control for extended periods during certain seasons of the year, the post installation temperature range allowed is an ambient room temperature between 32°F and 100°F (0°C- 37.7°C). This allowance is for floating floors only and does not apply to glue-down installations.

-

Avoid exposure to direct sunlight for prolonged periods, doing so may result in discoloration. During peak sunlight hours, the use of drapes or blinds is recommended. Excess temperature due to direct sunlight can result in thermal expansion and UV fading.

-

Install product after all other trades have completed work that could damage the flooring.

-

If cabinets are to be installed on top of the flooring (including islands), that area of material must be fully adhered to the subfloor (including an additional 2’ beyond the cabinets and islands).

-

-

To minimize shade variation, mix and install flooring from several cartons.

-

Inspect all flooring for damage before installing. If you have any concerns about the product fit or finish, call Shaw Information Services at 1-800-441-7429. Claims will not be accepted for flooring that has been cut to size and/or installed.

-

Use cementitious patching and leveling compounds that meet or exceed maximum moisture level and pH requirements. Use of gypsum-based patching and/or leveling compounds which contain Portland or high alumina cement and meet or exceed the compressive strength of 3,000 psi are acceptable.

-

Installation Methods: Floating (on, above or below grade) / Glue Down (on, above or below grade)

-

Required perimeter expansion spacing for Floating or Glue Down installation is as follows:

For areas less than 2500 sq. ft. use 1/4" gap

For areas larger than 2500 sq. ft. use 1/2" gap. -

WPC flooring is waterproof and reliably secures the flooring panels on all four sides. However, excessive moisture in the subfloor could promote mold, mildew, and other moisture related issues like the trapping of moisture emissions under the flooring, which may contribute to an unhealthy indoor environment.

-

Additional layer of 6 mil poly film or equal vapor retarder with a perm rating of .1 or less may be used as an additional layer of protection.

- A second underlayment is allowed under any currently sold resilient product with attached underlayment in a residential application. If installed over a second underlayment, this underlayment cannot be greater than 3 mm thick. IIC (ASTM E492-09) and STC (ASTM E90-09) lab testing on certain resilient products tested with and without a second layer of underlayment, to date, does not indicate that a second underlayment will provide additional acoustic benefit.

-

Crumb rubber underlayments are not an acceptable option for use with resilient floor coverings due to performance issues resulting from chemical incompatibilities.

II. SUBFLOOR INFORMATION

All subfloors must be clean, flat, dry, and structurally sound. The correct preparation of the subfloor is a major part of a successful installation. Subfloor must be flat: 3/16" in 10' or 1/8" in 6'.

A. Wood Subfloors

Do not install material over wood subfloors that lay directly on concrete or over dimensional lumber or plywood used over concrete. Refer to ASTM F1482 for panel underlayment recommendations.

-

Do not apply sheet plastic over wood subfloors.

- Basements and crawl spaces must be dry. Use of a 6 mil black polyethylene is required to cover 100% of the crawl space earth. Crawl space clearance from ground to underside of joist is to be no less than 18” and perimeter vent spacing should be equal to 1.5% of the total square footage of the crawl space area to provide cross ventilation. Where necessary, local regulations prevail.

-

DO NOT install over sleeper construction subfloors or wood subfloors applied directly over concrete.

-

All other subfloors - Plywood, OSB, particleboard, chipboard, wafer board, etc. must be structurally sound and must be installed following their manufacturer’s recommendations. Local building codes may only establish minimum requirements of the flooring system and may not provide adequate rigidity and support for proper installation and performance.

-

If needed add an additional layer of APA rated underlayment, fasten and secure according to the underlayment manufacturer’s recommendations.

-

Resilient flooring is not recommended directly over fire-retardant treated plywood or preservative treated plywood. An additional layer of APA rated 1/4" thick underlayment should be installed.

B. Concrete Subfloors

NEW AND EXISTING CONCRETE SUBFLOORS SHOULD MEET THE GUIDELINES OF THE LATEST EDITION OF ACI 302 AND ASTM F 710, “STANDARD PRACTICE FOR PREPARING CONCRETE FLOORS TO RECEIVE RESILIENT FLOORING” AVAILABLE FROM THE AMERICAN SOCIETY FOR TESTING AND MATERIALS, 100 BARR HARBOR DRIVE, WEST CONSHOHOCKEN, PA 19428; 610-832-9585; HTTP://WWW.ASTM.ORG.

-

Floors shall be smooth, permanently dry, clean, and free all foreign material such as dust, wax, solvents, paint, grease, oils, and old adhesive residue. The surface must be hard and dense, and free from powder or flaking.

-

If the adhesive residue is asphalt‐based (cut‐back), or any other type of adhesive is present, it must be removed by industry accepted methods such as mechanical removal or wet scraping.

-

If a chemical abatement has been performed, use Shaw Surface Prep EXT to remove any residual chemicals present. Once Shaw Surface Prep EXT has been properly cleaned and removed, apply one coat of Shaw MRP for additional protection.

-

Adhesive removal through the use of solvents or citrus adhesive removers is not recommended. Solvent residue left in or on the subfloor may affect the new adhesive and floor covering.

WARNING! DO NOT SAND, DRY SWEEP, DRY SCRAPE, DRILL, SAW, BEAD BLAST ORMECHANICALLY CHIP OR PULVERISE EXISTING RESILIENT FLOORING, BACKING, LINING FELT , ASPHALTIC “ CUT BACK” ADHESIVES OR OTHER ADHESIVES.

These products may contain either asbestos fibers and/or crystalline silica. Avoid creating dust. Inhalation of such dust is a cancer and respiratory tract hazard. Smoking by individuals exposed to asbestos fibers greatly increases the risk of serious bodily harm. Unless positively certain that the product is a non‐asbestos‐containing material, you must presume it contains asbestos. Regulations may require that the material be tested to determine asbestos content and may govern the removal and disposal of material. See current edition of the Resilient Floor Covering Institute (RFCI) publication Recommended Work Practices for Removal of Resilient Floor Coverings for detailed information and instructions on removing all resilient covering structures. For current information go to www.rfci.com.

-

Concrete slabs must be dry with no visible moisture.

-

Required Moisture Testing - maximum moisture level per ASTM 1869 CaCl is 8 lbs. and ASTM 2170 In-situ Relative Humidity 90% per 1000 sq.ft. in 24 hours.

-

Do not install over concrete with a history of high moisture or hydrostatic conditions. Excessive moisture in the subfloor could promote mold, mildew, and other moisture related issues like the trapping of moisture emissions under the flooring, which may contribute to an unhealthy indoor environment. Shaw Industries does not warrant nor is responsible for damage to floor covering due to moisture related issues.

-

pH level of concrete should be between 7-10.

-

The final responsibility for determining if the concrete is dry enough for installation of the flooring lies with the floor covering installer.

NOTE: IT MAY NOT BE THE FLOOR COVERING INSTALLER'S RESPONSIBILITY TO CONDUCT THESE TESTS. IT IS, HOWEVER, THE FLOOR COVERING INSTALLER'S RESPONSIBILITY TO MAKE SURE THESE TESTS HAVE BEEN CONDUCTED, AND THAT THE RESULTS ARE ACCEPTABLE PRIOR TO INSTALLING THE FLOOR COVERING. WHEN MOISTURE TESTS ARE CONDUCTED, IT INDICATES THE CONDITIONS ONLY AT THE TIME OF THE TEST.

LIGHTWEIGHT CONCRETE

All recommendations and guarantees as to the suitability and performance of lightweight concrete under resilient flooring are the responsibility of the lightweight concrete manufacturer. The installer of the lightweight product may be required to be authorized or certified by the manufacturer. Correct on-site mixing ratios and properly functioning pumping equipment are critical. To ensure proper mixture, slump testing is recommended.

-

Lightweight aggregate concretes having dry densities greater than 90 lbs. per cubic foot may be acceptable under resilient flooring.

-

Concrete slabs with heavy static and/or dynamic loads should be designed with higher strengths and densities to support such loads.

-

Surface must be permanently dry, clean, smooth, free of all dust, and structurally sound.

-

Perform Bond testing to determine compatibility of adhesive to the substrate. Shaw 9050 primer (or equivalent / comparable product) can be utilized to promote adhesion.

-

Three internal relative humidity tests should be conducted for areas up to 1000 sq. ft. One additional test, for each additional 1000 sq. ft.

Radiant Heating: Radiant-heated subfloor systems can be concrete, wood or a combination of both.

The heating systems components must have a minimum of 1/2" separation from the flooring product. The system must be on and operational for at least 2 weeks prior to installation to reduce residual moisture. Three days prior to installation lower the temperature to 65°F, after installation gradually increase the temperature in increments of 5°F to avoid overheating. Maximum operating temperature should never exceed 85°F. Use of an in-floor temperature sensor is recommended to avoid overheating. Contact the manufacturer of your radiant heating system for further recommendations.

- Electric Radiant Floors: consist of electric cables (or) mats of electrically conductive materials mounted on the subfloor below the floor covering. Mesh systems are typically embedded in thin-set. When embedding the system components, use cementitious patching and leveling compounds that meet or exceed Shaw’s maximum moisture level and pH requirements. Use of gypsum-based patching and/or leveling compounds which contain Portland or high alumina cement and meet or exceed the compressive strength of 3,000 psi are acceptable.

- Hydronic Radiant Floors: pump heated water from a boiler through tubing laid in a pattern under the flooring. Typically installed in channels under a wooden subfloor (or) imbedded in concrete slabs. Requires the installer follow a specific nailing pattern to avoid penetration of the heat system.

C. Existing Floor Coverings

Flooring can be installed over most existing hard–surface floor coverings, provided that the existing floor surface is fully adhered, clean, flat, dry, structurally sound and free of deflection.

- Existing sheet vinyl floors should not be heavily cushioned and not exceed more than one layer in thickness. Soft underlayment and soft substrates will compromise the product's locking ability as well as diminish its indentation resistance.

- Installation is NOT allowed over any type of carpet.

- Do NOT install over wood floors adhered to concrete.

- This product can be installed over existing ceramic/porcelain tile products with up to a 1/4 inch wide grout joint. If the grout joint width exceeds 1/4 inch, a cementitious patching compound should be used to fill the grout joint to make it smooth with the surface of the tile.

- Raised access panels must be stable, level, flat, free and clean of existing adhesives

- 24" x 24" panels are recommended.

- Lippage (variation of height) between of panels must not exceed 0.295” (0.75 mm)

- Gaps between panels must not exceed 0.039” (1 mm)

- There should be no deflection of the individual panels – Concave less than 0.0295” (0.75 mm)

- Flatness 1/8” in 10’

- Stagger the flooring tiles/planks to overlap the access panels

- Telegraphing of access panel seams may be visible and is not considered a product defect nor warranted by the flooring manufacturer.

If needed, overlay the panels with a 1⁄4” (6 mm) plywood and properly fasten to the access panels prior to the installation of the floorcovering. Prior to underlayment installation, repair any loose or unstable panels. Use the appropriate installation methods for the product.

III. INSTALLATION

Tools: Tape Measure, Utility Knife, Jigsaw, Tapping Block or Rubber Mallet, Pull Bar, ¼" Spacers, T-Square, Safety Glasses, Broom or Vacuum and, if necessary, tools for subfloor repair.

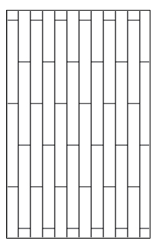

Floating Installation

WPC flooring is designed to be installed utilizing the floating method. Proper expansion space 1/4” (6.35 mm) is required. Undercut all doorjambs. Do not fasten wall moldings and or transition strips to the flooring.

If alternative adhesives are used, a bond test should be performed to ensure compatibility.

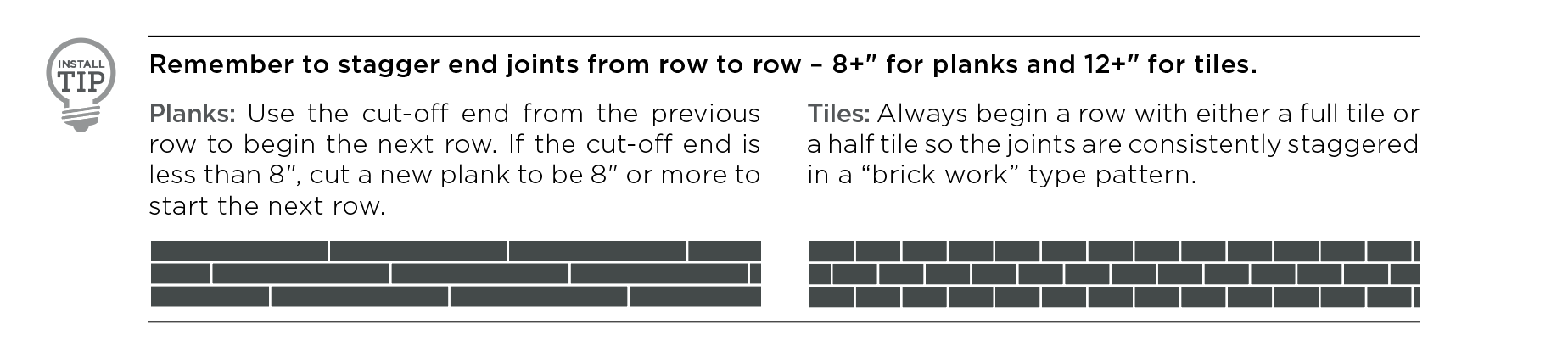

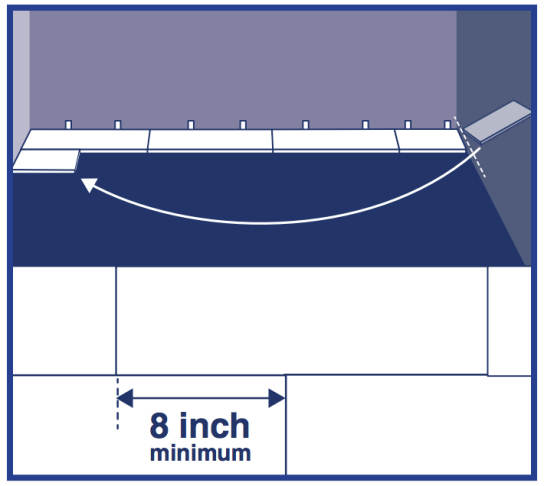

Flooring patterns must be installed in a staggered (offset) pattern.

LAYOUT

Step 1: Begin installation working from left to right. Insert spacers at ends and edges where flooring meet wall. |

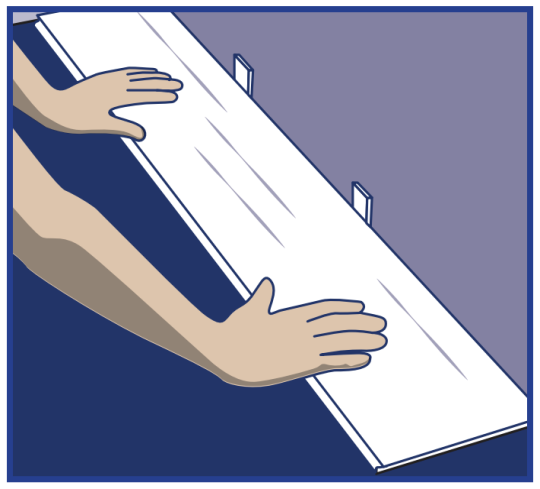

Step 2: Lock short end of flooring by inserting tongue into groove at an angle and drop in place. At end of the row, measure and cut the flooring to complete the row. Install the cut edge closest to the wall. |

Step 3: Use leftover flooring from first row as starter for second row. There must be at least 20cm between flooring end joints on adjacent rows. FOR TILE INSTALLATIONS: The distance between end joints should be equal to 30cm for proper appearance. |

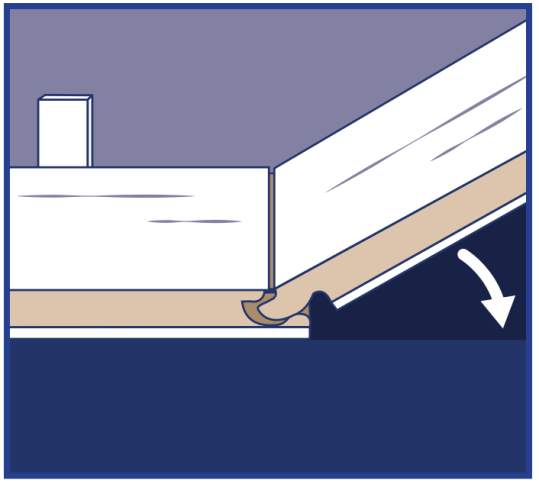

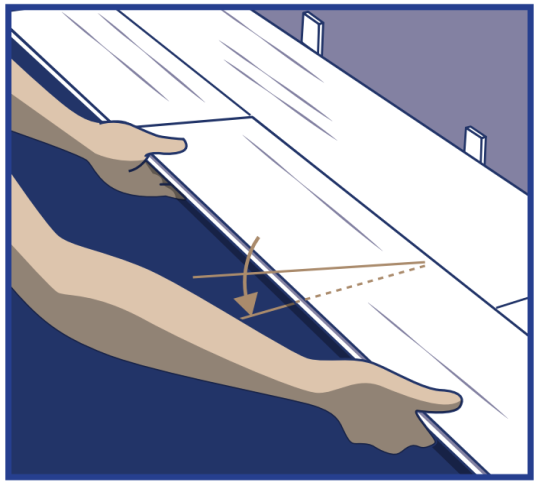

Step 4: Lock long edge of flooring by inserting tongue into groove at an angle and drop in place. Slide flooring toward end of previously installed flooring until the tongue just touches the groove. |

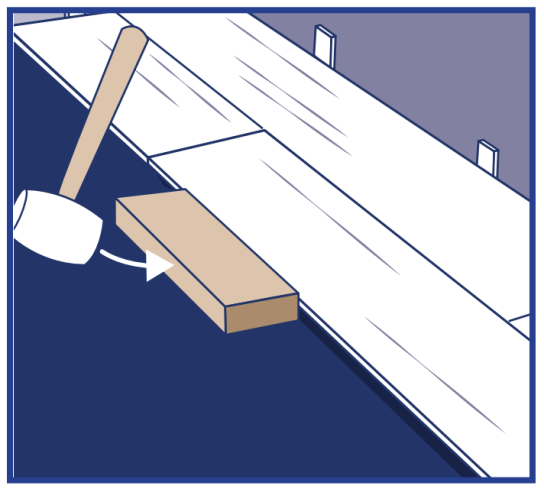

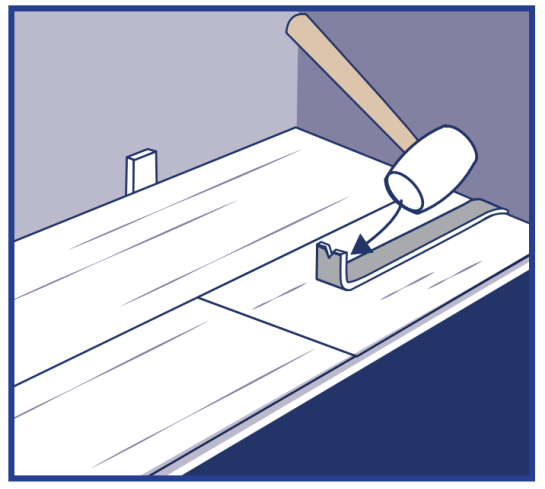

Step 5: IMPORTANT! Use hammer and tapping block to tap long edge of plank to ensure a tight fit. ANY GAPPING CAN COMPROMISE THE LOCKING SYSTEM! |

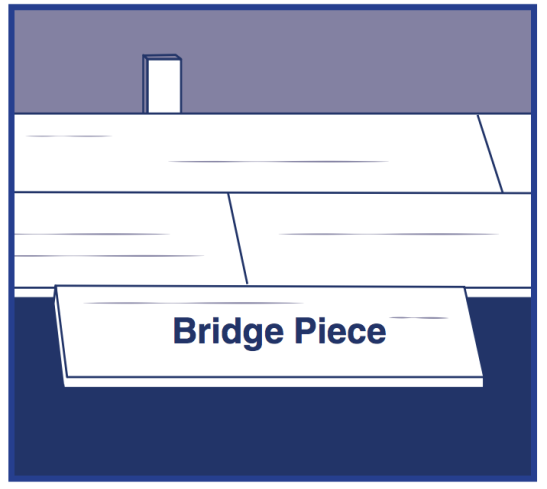

Step 6: Attach a scrap piece of floor to bridge the gap between ends of planks. |

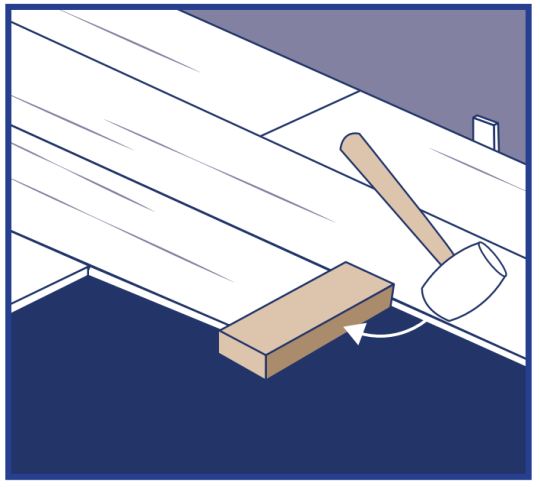

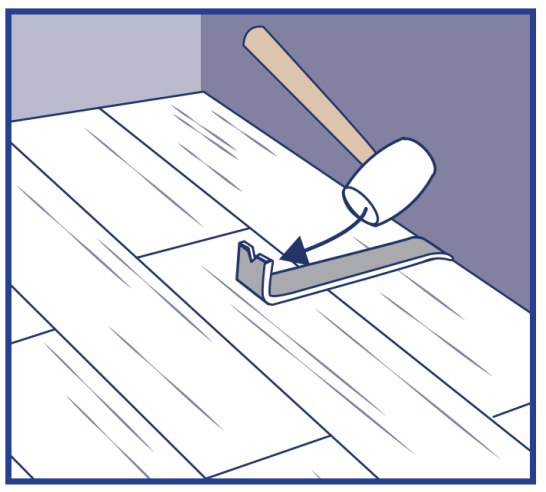

Step 7: Tap end of flooring with hammer and tapping block to lock ends of flooring together. Remove bridge and continue towards wall until installing the final flooring in the row.

|

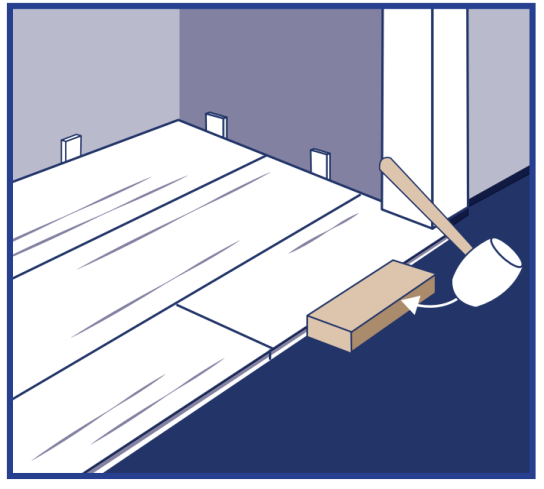

Step 8: Use hammer and pull bar to lock final piece in row. Insert spacer at end of row. Continue installation to final row. |

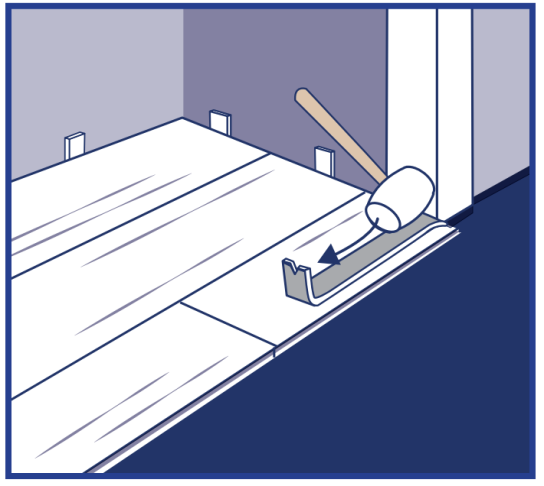

Step 9: Use hammer and pull bar to lock long edges of flooring on final row. |

Installing underneath door jambs: |

|

|---|---|

Step 1: Undercut space under door jamb to allow flooring to slide freely. Tap long edge with hammer and tapping block to lock long edge. |

Step 2: Use hammer and pull bar to lock this piece of flooring |

COMPLETION

- Protect all exposed edges of the flooring by installing wall molding and/or transition strips. Make sure that no plank will be secured in any way to the subfloor.

- For wet areas such as bathrooms caulk the perimeter of the floor with a flexible silicone caulk.

- Protect the finished flooring from exposure to direct sunlight to reduce fading and thermal expansion.

- Cutting resilient product into a fine point may lead to delamination. Use an ethyl cyanoacrylate based glue to help fuse the resilient point together. Be sure to clean all glue from the top surface immediately. Alcohol based glues may cause resilient products to swell.

- Adhering tape to the surface of your resilient flooring could damage the surface.

Do not use tape to secure floor protection directly to the floor during construction or renovation. Instead, adhere tape to the material used to protect the floor and secure it to the base molding along the wall. A material such as ram board can also be used to protect your flooring.

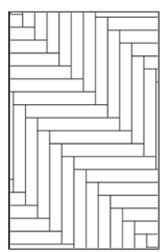

Herringbone Installation Guidelines for WPC Products

I. GENERAL INFORMATION

These installation guidelines apply to the WPC (Wood Polymer Composite) products only. All instructions and recommendations should be followed for a satisfactory installation.

- Acclimation of material prior to installation is not required, however, the floor covering should be installed in a climate controlled environment with an ambient temperature range between 55° - 85°F (13°-29°C) or average temperature of 70°F (21.1°C).

- For installations involving 3 season scenarios, meaning, the dwelling or installed space is without climate control for extended periods during certain seasons of the year, the post installation temperature range allowed is an ambient room temperature between 32F and 100F (0°- 37.7°C). This allowance is for floating floors only and does not apply to glue-down installations.

- Avoid exposure to direct sunlight for prolonged periods, doing so may result in discoloration. During peak sunlight hours, the use of the drapes or blinds is recommended. Excess temperature due to direct sunlight can result in thermal expansion and UV fading. In extreme situations of direct sunlight we suggest that the glue down method be used.

- Install product after all other trades have completed work that could damage the flooring.

- To minimize shade variation, mix and install planks from several cartons.

- Inspect all planks for damage before installing. If you have any concerns about the product fit or finish, call Shaw Information Services at . Claims will not be accepted for flooring that has been cut to size and/or installed.

- Use cementitious patching and leveling compounds that meet or exceed maximum moisture level and pH requirements. Use of gypsum-based patching and/or leveling compounds which contain Portland or high alumina cement and meet or exceed the compressive strength of 3,000 psi are acceptable.

- Installation – Floating or Glue down - installed on, above, or below grade with recommended adhesives.

- For installation in areas larger than 50’x50’, 2500 sq. ft. provide a minimum expansion space of 1/2” (12.7 mm) around the perimeter.

- WPC flooring is water/moisture resistant and reliably secures the flooring panels on all four sides. However, excessive moisture in the subfloor could promote mold, mildew, and other moisture related issues like the trapping of moisture emissions under the flooring, which may contribute to an unhealthy indoor environment.

- Additional layer of 6 mil poly film or equal vapor retarder with a perm rating of .1 or less with a may be used as an additional layer of protection.

- A second underlayment is allowed under any currently sold WPC Product with attached underlayment in a residential application. IIC (ASTM E492-09) and STC (ASTM E90-09) lab testing on certain SPC products tested with and without a second layer of underlayment, to date, does not indicate that a second underlayment will provide additional acoustic benefit. When used the second underlayment must be a maximum of 3 mm thick and have a minimum density of 190 kg/m3 or 11.7 lb. /ft3.

- Crumb rubber underlayments are not an acceptable option for use with resilient floor coverings due to performance issues resulting from chemical incompatibilities.

II. SUBFLOOR INFORMATION

All subfloors must be clean, flat, dry and structurally sound. The correct preparation of the subfloor is a major part of a successful installation. Subfloor must be flat – 3/16" in 10' or 1/8" in 6'.

A. Wood Subfloors

Do not install material over wood subfloors that lay directly on concrete or over dimensional lumber or plywood used over concrete. Refer to ASTM F1482 for panel underlayment recommendations.

- Do not apply sheet plastic over wood subfloors.

- Basements and crawl spaces must be dry. Use of a 6 mil black polyethylene is required to cover 100% of the crawl space earth. Crawl space clearance from ground to underside of joist is to be no less than 18” and perimeter vent spacing should be equal to 1.5% of the total square footage of the crawl space area to provide cross ventilation. Where necessary, local regulations prevail.

- All other subfloors - Plywood, OSB, particleboard, chipboard, wafer board, etc. must be structurally sound and must be installed following their manufacturer’s recommendations. Local building codes may only establish minimum requirements of the flooring system and may not provide adequate rigidity and support for proper installation and performance. If needed add an additional layer of APA rated underlayment, fasten and secure according to the underlayment manufacturer’s recommendations.

- Resilient flooring is not recommended directly over fire-retardant treated plywood or preservative treated plywood. An additional layer of APA rated 1/4" thick underlayment should be installed.

B. Concrete Subfloors

NEW AND EXISTING CONCRETE SUBFLOORS SHOULD MEET THE GUIDELINES OF THE LATEST EDITION OF ACI 302 AND ASTM F 710, “STANDARD PRACTICE FOR PREPARING CONCRETE FLOORS TO RECEIVE RESILIENT FLOORING” AVAILABLE FROM THE AMERICAN SOCIETY FOR TESTING AND MATERIALS, 100 BARR HARBOR DRIVE, WEST CONSHOHOCKEN, PA 19428; 610-832-9585; HTTP://WWW.ASTM.ORG.

- Floors shall be smooth, permanently dry, clean, and free all foreign material such as dust, wax, solvents, paint, grease, oils, and old adhesive residue. The surface must be hard and dense, and free from powder or flaking.

- New concrete slabs must be dry. Maximum moisture level per CaCl test method is 8 lbs. per 1000 in 24 hr. Maximum level for ASTM 2170 In-situ Relative humidity test method - 90%.

- Do not install over concrete with a history of high moisture or hydrostatic conditions. Excessive moisture in the subfloor could promote mold, mildew, and other moisture related issues like the trapping of moisture emissions under the flooring, which may contribute to an unhealthy indoor environment. Shaw Industries does not warrant nor is responsible for damage to floor covering due to moisture related issues.

- pH level of concrete should be between 7-10.

- The final responsibility for determining if the concrete is dry enough for installation of the flooring lies with the floor covering installer.

NOTE: IT MAY NOT BE THE FLOOR COVERING INSTALLER'S RESPONSIBILITY TO CONDUCT THESE TESTS. IT IS, HOWEVER, THE FLOOR COVERING INSTALLER’S RESPONSIBILITY TO MAKE SURE THESE TESTS HAVE BEEN CONDUCTED, AND THAT THE RESULTS ARE ACCEPTABLE PRIOR TO INSTALLING THE FLOOR COVERING. WHEN MOISTURE TESTS ARE CONDUCTED, IT INDICATES THE CONDITIONS ONLY AT THE TIME OF THE TEST.

LIGHTWEIGHT CONCRETE

All recommendations and guarantees as to the suitability and performance of lightweight concrete under resilient flooring are the responsibility of the lightweight concrete manufacturer. The installer of the lightweight product may be required to be authorized or certified by the manufacturer. Correct on-site mixing ratios and properly functioning pumping equipment are critical. To ensure proper mixture, slump testing is recommended.

- Lightweight aggregate concretes having dry densities greater than 90 lbs. per cubic foot may be acceptable under resilient flooring.

- Concrete slabs with heavy static and/or dynamic loads should be designed with higher strengths and densities to support such loads.

- Surface must be permanently dry, clean, smooth, free of all dust, and structurally sound.

- Perform Bond testing to determine compatibility of adhesive to the substrate. Shaw 9050 primer can be utilized to promote adhesion.

- Three internal relative humidity tests should be conducted for areas up to 1000 SF. One additional test, for each additional 1000 SF.

Radiant Heating: Radiant-heated subfloor systems can be concrete, wood or a combination of both. The heating systems

components must have a minimum of 1/2" separation from the flooring product. The system must be on and operational for at least 2 weeks prior to installation to reduce residual moisture. Three days prior to installation lower the temperature to 65 degrees, after installation gradually increase the temperature in increments of 5° F to avoid overheating. Maximum operating temperature should never exceed 85°F. Use of an in-floor temperature sensor is recommended to avoid overheating. Contact the manufacturer of your radiant heating system for further recommendations.

- Electric Radiant Floors: consist of electric cables (or) mats of electrically conductive materials mounted on the subfloor below the floor covering. Mesh systems are typically embedded in thin-set. When embedding the system components, use cementitious patching and leveling compounds that meet or exceed Shaw’s maximum moisture level and pH requirements. Use of gypsum-based patching and/or leveling compounds which contain Portland or high alumina cement and meet or exceed the compressive strength of 3,000 psi are acceptable.

- Hydronic Radiant Floors: pump heated water from a boiler through tubing laid in a pattern under the flooring. Typically installed in channels under a wooden subfloor (or) imbedded in concrete slabs. Requires the installer follow a specific nailing pattern to avoid penetration of the heat system.

! WARNING! DO NOT SAND, DRY SWEEP, DRY SCRAPE, DRILL, SAW, BEADBLAST OR MECHANICALLY CHIP OR PULVERIZE EXISTING RESILIENT FLOORING, BACKING, LINING FELT, ASPHALTIC “CUTBACK” ADHESIVES OR OTHER ADHESIVES.

These products may contain either asbestos fibers and/or crystalline silica. Avoid creating dust. Inhalation of such dust is a cancer and respiratory tract hazard. Smoking by individuals exposed to asbestos fibers greatly increases the risk of serious bodily harm. Unless positively certain that the product is a non-asbestos-containing material, you must presume it contains asbestos. Regulations may require that the material be tested to determine asbestos content and may govern the removal and disposal of material. See current edition of the Resilient Floor Covering Institute (RFCI) publication Recommended Work Practices for Removal of Resilient Floor Coverings for detailed information and instructions on removing all resilient covering structures. For current information go to www.rfci.com.

C. Existing Floor Coverings

Flooring can be installed over most existing hard–surface floor coverings, provided that the existing floor surface is fully adhered, clean, flat dry structurally sound and free of deflection.

- Existing sheet vinyl floors should not be heavily cushioned and not exceed more than one layer in thickness. Soft underlayment and soft substrates will compromise the product's locking ability as well as diminish its indentation resistance.

- Installation is NOT allowed over any type of carpet.

- Do NOT install over wood floors adhered to concrete.

- Never use solvents or citrus adhesive removers to remove old adhesive residue. Solvent residue left in and on the subfloor may affect the new floor covering.

III. INSTALLATION

Tools: Tape Measure, Utility Knife, Jigsaw, Tapping Block or Rubber Mallet, Pull Bar, ¼" Spacers, T-Square, Safety Glasses, Broom or Vacuum and, if necessary, tools for subfloor repair.

Floating Installation

WPC plank flooring is designed to be installed utilizing the floating method. Do NOT secure the planks to the subfloor when using the floating installation method. Proper perimeter expansion space 1/4”, (6.35 mm) is required. Undercut all doorjambs. Do not fasten wall moldings and or transition strips to the planks.

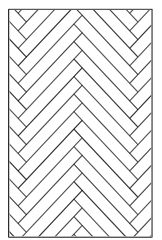

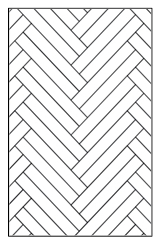

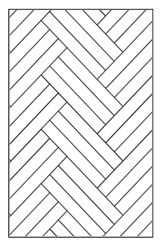

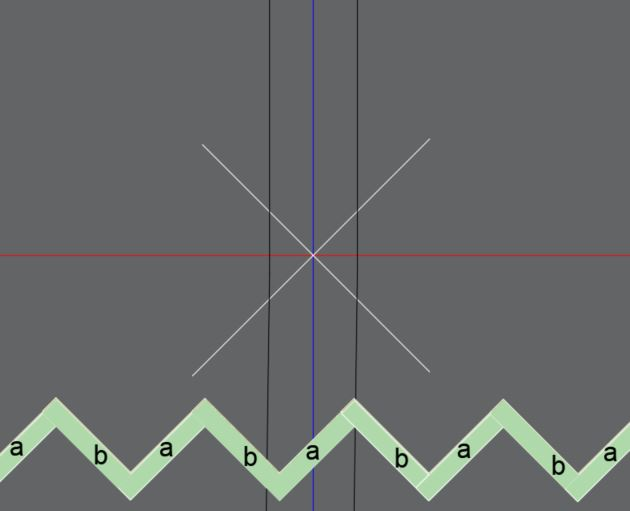

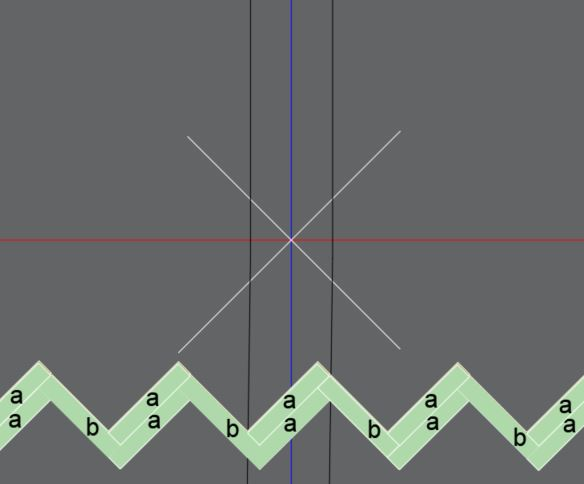

Alternate Installation Patterns:

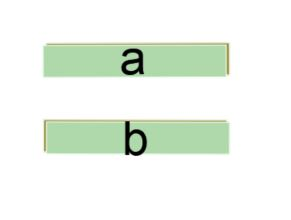

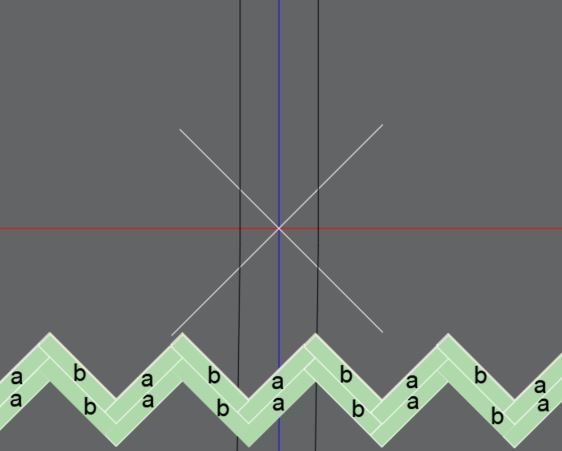

The herringbone planks can be identified by:

a – Herringbone plank with groove on right end side.

b – Herringbone plank with groove on left end side.

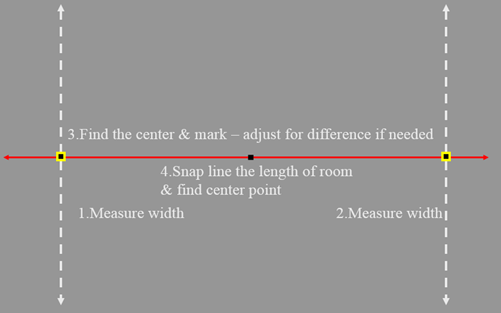

Getting Started

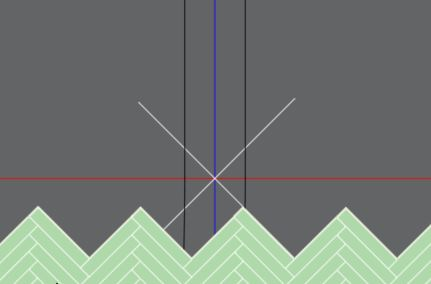

|

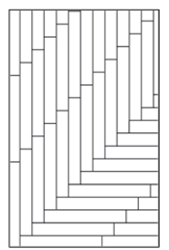

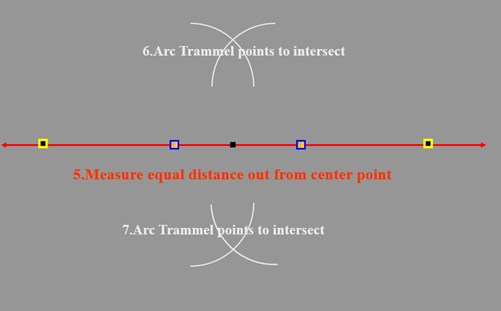

1. Establish a primary line. |

|

2. Establish the secondary line. |

|

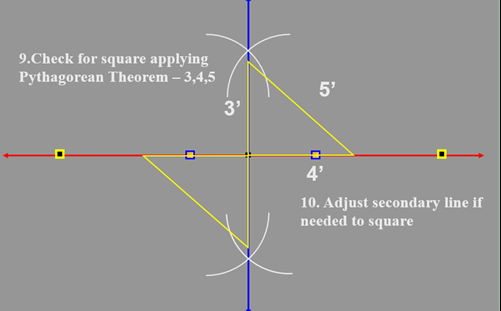

3. Once you have established the primary and secondary line, check for square - use the 3’, 4’, 5’ method (otherwise known as Pythagorean Theorem). For larger areas you can 6’, 8’, and 10’ and so on. |

|

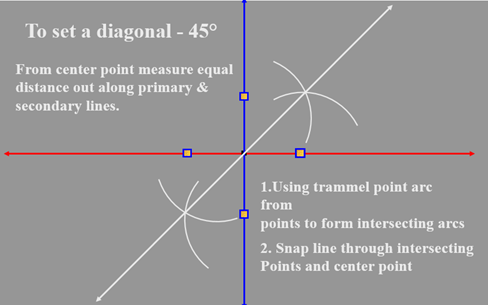

4. To set diagonals – first line - 45 degrees. |

|

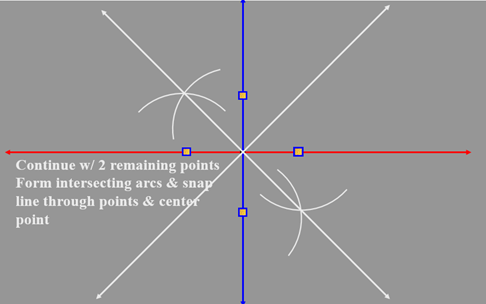

5. Second diagonal – 45 degrees. 6. Once all the lines are established the pattern can be laid from the primary lines or use the diagonal lines to install on a 45 degree angle. |

|

7. After you have determined the direction to install the pattern you will need to lay out a plank and establish reference lines (secondary) to keep the pattern from running off. Prior to installation always refer to the installation guidelines of the product for complete installation details. |

|

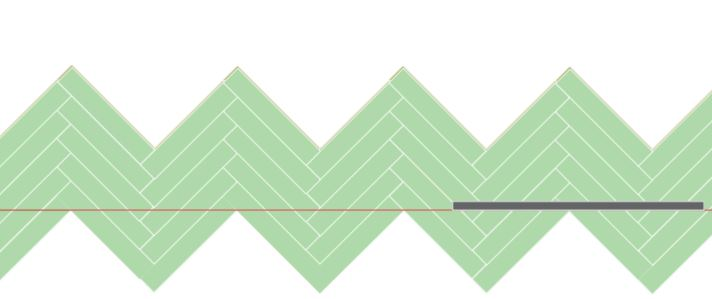

8. After the secondary lines are created. Move an (a) plank to the start wall and align groove side end point and tongue side end point on secondary lines. |

|

9. Install the planks alternating (a) and (b) toward the outside walls. This will create a centered layout to the room. |

|

10. After the initial herringbone row is installed, start from the back right corner and install the (a) planks skipping the (b) across the width of the herringbone layout. |

|

11. Once the (a) planks are installed proceed with installing the (b) planks across the width of the herringbone layout. |

|

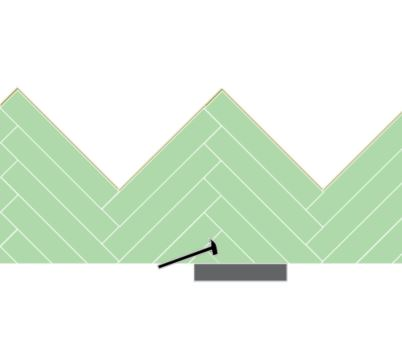

12. After 4-5 rows of the herringbone have been installed across the width, slide out from the wall 6-12 inches. Chalk a line across the width of the planks to remove the excess material installed. Take a straight edge and score the product several times with a utility knife along the chalk line. |

|

13. Place a block underneath the material on the side of the chalk line for the material to keep in the install. Take a hammer and strike the excess side to break away. |

|

14. Process with the installation from the right to left alternating the (a) and (b) planks during the installation. |

Final Inspection: After the floor has been cleaned, inspect the floor for nicks, scratches, gaps or planks that may have moved during installation, as well as, any other imperfections that need attention.

COMPLETING THE JOB – ALL INSTALLATIONS

- Sweep or vacuum floor

- Clean the floor with proper hardwood floor cleaner

- Install transition pieces - i.e. thresholds, t-moldings, base boards and quarter round. Nail moldings to wall, not the floor.

- Inspect final floor for nicks and or minor gaps.

- Unused material should be left with owner and stored in a dry place in case of future repairs are needed.

- Use plywood or hardboard when moving heavy appliances or furniture across floor.

Floor Protection During Construction: After installation, if you choose to protectively cover the floor, cover the floor completely, since some species are light-sensitive and uncovered areas may change color. Use a covering material with a vapor permeance (perm rating) of 1 perm or more (tested I accordance with ASTM E-96) to avoid trapping moisture/vapor on or within the floor. Any covering should be taped, using a low-adhesion tape, to base or shoe moldings. Avoid taping to finished flooring. When taping paper or sheets together, tape them to each other, not to the floor.

Moldings Help You Make Easy Transitions

- T-Moldings: Used to create a transition between floor coverings of similar heights or to cover an expansion gap.

- Stair Nosing: Used in conjunction with flooring installed on steps or provide a finished edge. Secure by gluing and nailing/ screwing down into place. Predrill holes to avoid splitting.

- Reducer Strips: Used to transition floor coverings of differing heights- wood floor to vinyl, vinyl composition tile, or low-pile carpet. Can also be used to border a fireplace.

- Thresholds: Used to transition floor coverings or to create a break between floor coverings – wood to carpet, can be used as a trim molding around fireplaces or sliding glass doors.

- Shoe Base Moldings: Used to cover the expansion space between the floor and vertical surfaces. Can be used as a substitute for Quarter Round moldings when space is a limitation.

- Quarter Round Moldings: Used to cover the expansion space between the Wall Base and your hardwood floor. You can also use them to make smooth transitions between the floor and cabinetry.

- Wall Base Moldings: Can be stained and finished to the color of the flooring to be used an alternative to painted baseboards.

RESIDENTIAL RESILIENT MAINTENANCE

Proper care will help protect and maintain the appearance and performance of your resilient floor.

A Care Program Consists of Key Areas:

-

Post-Construction Maintenance

-

Preventative Maintenance

-

Routine Maintenance

-

Spot and Spill Removal.

For New Construction or Renovation: Construction dust and joint compound can be deposited on the flooring. If it is not completely removed and then wet mopped, it will create a haze on the surface of the flooring.

POST-CONSTRUCTION MAINTENANCE

-

Dry mop floor using a microfiber mop pad or appropriate floor vacuum to remove dust particulate from the floor.

-

Spray neutral pH cleaner, such as Encore, COREtec Cleaner or equivalent neutral pH floor cleaner, onto the floor in manageable areas (spray mist will dry quickly). Use a microfiber wet mop pad to mop the floor with cleaner. If pad becomes dirty, be sure to replace the pad with a new microfiber wet mop pad. Mop floor in sections.

-

Always rinse the floor with water only by mopping with water to remove any remaining residue from the floor.

In the event where dry wall dust/construction dust is mopped with water only, a residue film will appear on the floor after drying. Use the process below to remove the film from the floor.

PROCESS TO REMOVE CONSTRUCTION RESIDUE OR CLOUDY FILM FROM RESILIENT FLOORING

-

Dry mop floor to remove any construction dust or exterior soil tracked onto the flooring. Use microfiber dry mop pad. If microfiber dry mop pad gets dirty, replace pad with a clean pad.

-

Spray neutral pH cleaner, such as Encore, COREtec Floor Cleaner or equivalent neutral pH floor cleaner onto the floor in manageable areas (spray mist will dry quickly). Clean floor in sections. For smooth surface, use a low rpm (175 rpm) buffer with a 3M red pad on flooring with neutral pH cleaner applied to the floor to remove the residue film. (Never Dry Buff). For embossed or textured flooring, use a cylindrical brush scrubber, such as the Clark MA10 12E Scrubber and a neutral pH floor cleaner applied to the floor to remove the residue film.

-

Using a wet microfiber mop pad, rinse with water only to remove any remaining residue from the flooring. When wet mop pad becomes dirty, be sure to replace the pad with a new microfiber wet mop pad.

-

Repeat steps #2 and #3, if necessary.

When the resilient flooring is cleaned properly, the floor will have the same visual as right out of the box!

PREVENTATIVE MAINTENANCE

- Always protect floors when moving heavy objects to prevent permanent scratches and tears.

- Adhering tape to the surface of your resilient flooring could damage the surface.

Do not use tape to secure floor protection directly to the floor during construction or renovation. Instead, adhere tape to the material used to protect the floor and secure it to the base molding along the wall. A material such as ram board can also be used to protect your flooring. - Use appropriate wide floor protectors under tables, chairs, and any other heavy home furnishing to avoid permanent damage.

- Walk-off mats should be used at all entrances to absorb soil and moisture. If mats are placed directly on top of the resilient floors, use mats without latex or rubber backings to avoid possible discoloration.

- Use appropriate window coverings to avoid direct sunlight as this can fade the color of the flooring.

- Avoid using mop and shine products on your resilient flooring.

- Some disinfectants contain chemicals that can stain, discolor and cause general harm to your flooring product. Quaternary Ammonium Salts are among those that have been found to be harmful to your flooring when used over time. Take care to choose pH neutral products only.

ROUTINE MAINTENANCE

- Daily removal of dirt and dust is important to prevent particles from abrading the surface of resilient floors. Sweeping, dust mopping, and vacuuming are recommendations to remove soil particles that can result in scratches and worn appearances. Do not use vacuums with rotating beater bars on hard surfaces.

- Periodic wet cleaning will be necessary to help maintain the floor’s appearance. Always pre- vacuum or dust mop before any type of wet cleaning. Appropriate vinyl floor cleaning equipment and cleaning agents (neutral pH floor cleaners) are recommended. Do not use abrasive cleaners or cleaning agents that leave dull residues on the surface of the floors. Follow the cleaning manufacturer’s instructions for damp mopping and application. If rinsing is necessary, use clean water and expedite drying with air movers or fans.

- Encore, COREtec neutral pH floor cleaner or equivalent floor cleaner are recommended for general spotting and cleaning.

- Avoid using mop and shine products on your resilient flooring.

- Products containing bleach and steam mops are not recommended.

SPOT & SPILL REMOVAL

Our flooring products are engineered to resist and minimize common staining.

- Absorb wet spills as quickly as possible by blotting with paper or cloth towels. Rinse with water if necessary and blot dry.

- Dried spots should be removed by gentle agitation and rinsed with water. Blot dry.

- Use Encore, COREtec cleaning products or products formulated for vinyl floor cleaning. Do not use detergents or abrasive cleaners since these products can leave a dull residue.

- Use rubbing alcohol (isopropyl alcohol) with a clean white cloth for spots requiring a solvent type cleaner that water and cleaning agents cannot remove.

- Please note that some stain conditions may become permanent.

Safety Caution: The surfaces of resilient floors change during wet cleaning and finish applications. Use appropriate safety measures.